product

- Atomic Force Microscope

- FE-SEM

- Hi-SEM

- Optical Interferometry System

- Sample Preparation

- Tabletop Microscope

- Transmission Electronic Microscope

- X-Ray Spectroscopy

- Fluorescence Spectrophotometer

- Amino Acid Analyzer

- Atomic Absorption Spectrophotometer

- Autotitrator

- Mercury Analyzer

- UV-VIS Spectrophotometer

- High Performance Liquid Chromatography

- Thermal Analyzer

- Automatic Moisture and Ash Content Analyzer

- Fluorescence Spectrophotometer

- Fluorescence Steady State & Life Time / Flash Photolysis

- Mercury Analyzer

- Raman Spectroscopy

- UV-VIS Spectrophotometer

- Mass Spectrometer

- FTIR Spectrometer

- Chromatography Data System

- Gas Chromatography

- Gas Chromatography-Mass Spectrometer (GC-MS)

- Liquid Chromatography

- Sampler and sample pretreatment system

- Column and Consumable

- Amino Acid Analyzer

- Anaerobic & Hypoxic Chambers

- Autoclave & Sterilization

- Biological Safety Cabinets & Clean Benches

- Blood bank & Phamacy Freezer

- Cryopreservation Systems

- DNA & RNA Purification

- Environmental Chambers

- Freezer Dryer

- High Capacity Centrifuge

- High Speed Centrifuge

- Lab Water Purification

- Lab Oven & Incubator

- Life Science

- Mixer

- Pipette

- Tabletop Centrifuge

- Ultracentrifuge

- ULT Freezer

- Temperature Forcing System

- Precisa Analytical Balances

- Precisa Micro Balances

- Precisa Precision Balances 0.001g

- Precisa 520 PB/PT Analytical and Precisa balances

- Preicsa 320 XB Series Balances

- Precisa 165 BJ Series Balances

- Precisa 410 SRS/SRC Series Scale

- Precisa 365 EM/330 XM Moisture Analyzers

- Precisa 490 Series Industrial Scales

- Precisa 321 LX/LS-STB Series Stirrer Balances

- Precisa 321 LG Series Balances

- Standard Balances

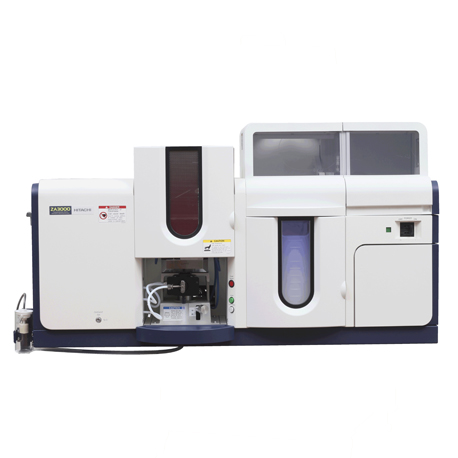

Hitachi ZA3000 Series

The ZA3000 Series Polarized Zeeman Atomic Absorption Spectrophotometer is now available as a successor to the Z-2000 Series Atomic Absorption Spectrophotometer that has earned a high evaluation from the customers.

The ZA3000 Series is available in three different models --- flame version (ZA3300), furnace version (ZA3700), and tandem version (ZA3000). All three versions utilize the polarized Zeeman dual detection system, and feature high sensitivity and precision over a wide range of analyses.

The ZA3000 series Polarized Zeeman Atomic Absorption Spectrophotometer preserve the basic performance of the high precision and sensitive analysis of Z-2010 series, the series incorporates the Twin Injection Technology as the new technology.

The ZA3000 Series is the new ultimate analysis equipment which considered the improvement of analytic reliability and function, and the environmental performance.

Download- Hong Kong SAR

- Singapore

- Thailand

Features:

1. Tandem Type[ZA3000], Flame Type[ZA3300], Furnace Type[ZA3700] --- Three models are available.

The ZA3000 Series Atomic Absorption Spectrophotometers

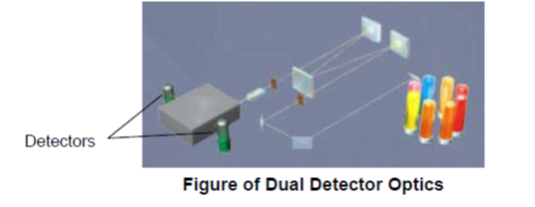

2. Polarized Zeeman method enabling correction over the full wavelength

range is adopted and dual detectors will bring high accuracy and sensitivity.

Increased sensitivity

Because ZA3000 series preserve the Polarized Zeeman Dual Detection System of Z-2000 series, ZA3000 series can analyze the As, Se, and Sb in environmental water by the Hollow Cathode Lamp. Data in the figure below was obtained by injecting 40 μL of a standard solution of As at 1 μg/L and measuring under the same conditions in graphite furnace analysis.

Background correction by the Polarized Zeeman method.

The Hollow Cathode Lamp used for measurement can perform background correction over a full wavelength range.

It is the feature of the Polarized Zeeman method that atomic absorption and background correction can be performed with the same wavelength and the same spectral band width.

Stable baseline

By using the Polarized Zeeman correction method which provides a baseline which has high stability, the analysis of Cd in brown rice at a level significantly lower than 0.4 ppm is possible even by flame analysis.

3. Flame analyses and graphite furnace analyses can be done without replacing the atomizer.

- Atomizer selection can be made simply through the software. It is not necessary to replace the atomizer unit nor adjust the optical axis.

- The flame method is suitable for mg/L-level analyses, and the graphite furnace method is applicable to μg/L-level analyses and samples in small quantity. Depending on the concentration of analyte and the quantity of sample, you can choose a suitable analytical method.

4. Dedicated the Flame/Furnace model can achieve a compact size.

Compared with former models (Z-5300/5700), width:

1,150 mm → 800 mm (30% reduction)

5. Operating efficiency has been further enhanced by flame switches.

The remote-control switches previously available at option are now replaced with ones standard equipped on the main unit. Manual analysis can be carried out by switch operation on the instrument front.

6. Autosampler for graphite furnace is embedded in the main unit and dust cover is a standard feature.

Improved operability of sample rack unit, which is accessed frequently, by dividing dustproof cover into two parts.

7. Improved visibility of atomization unit by means of LED lighting.

8. Twin injection technology

Twin injection technology can measure the Sb in environmental water (0.2μg/L) without in-furnace concentration.

* Pyrotube-D HR is required to use the twin injection function.

9. Cuvette Memory Suppression Function

In measurement of a high melting point element, in order to remove the bad influence to the next measurement by the memory effect, the temperature program for cleaning can be automatically run between sample measurement.

10. Automatic Bumping Detection Function

Bumping of the sample in a dry stage which worsens measurement accuracy is detected, and the "P" mark is attached to the measurement result of the possible sample of bumping. By this function, the possibility of bumping can be checked also after measurement. It is information effective in the factor analysis of fault measurement reproducibility. In addition users can create the drying condition which controlled bumping by using together with a temperature program automatic creation function.

11. Automatic Creation of Temperature Program Support Function

Dry, Ash and Atom temperature are changed in each stage, automatic measurement is performed, and the temperature program from which the maximum ABS or the minimum RSD is obtained is created.

12. Speedy dispensing by the Auto Sampler.

When you inject multiple samples into a cuvette to use, for example, matrix modifiers for a single measurement, the first sample is aspirated by the autosampler nozzle, followed by the next sample by the force of air. After the samples are aspirated, all the samples are injected into the cuvette. You can save the measurement time as the sample pipetting time is faster than the measurement with no sequential injection. You can improve the mixture of samples and matrix modifiers because of the strong discharging pressure by using this function including the matrix modifiers. Thus, you can reduce the volume of the matrix modifiers compared with the measurement with no sequential injection. You can also expect the similar effect by reducing the concentration.

13. Apply the Zeeman effect to the hydride generation method.

After Z-2010 series Hitachi Zeeman Atomic Absorption Spectrophotometer applies the Zeeman effects to heating quartz - hydride generation method.

Because each light path to correct the lamp drift and back ground pass through heating quartz cell as same light axis, hydride generation atomic absorption spectrometry is stable baseline and low noise level analysis.

14. Standby power consumption saving setup

· Power saving mode

The Hollow Cathode Lamp is turned off automatically when device operation is not operated for 1 hour. The motor of the autosampler for Graphite Furness is also turned off.

· Water saving mode [Only ZA3000]

The cooling water is stopped automatically when device operation is not operated for 10 minutes except in the case of Frame burning.

15. Analysis assist, real-time QC and Easy Start functions assure ease of use.

* This feature is only for flame AAS manual analysis mode.

16. ZA3000 software comes with rich features and easy operation by an improved GUI.

Monitor Window

The signals during measurement (Zeeman correction and background signal) are monitored in real-time. One screen can display real-time monitor, data and working curve. Thus, data recognition is easy.

Method Window

Allows easy setting of analytical conditions just by clicking icons at the top of the window in order starting from the left, and then entering your desired parameters.

Data Process Window

Analysis of multi-elements and data processing are easily performed. Result data, profile and working curve are shown in one window. Thus, the operation is very easy. Output data after data processing is used in a report generator as well as in a regular format. By this, the data can be customized freely using Excel? format.

17. For making a report, ZA3000 software comes with a customization feature (Report Generator) using Microsoft? Excel?.

18. A variety of safety functions are incorporated.

- Full time monitoring of the maximum and minimum pressure of acetylene gas-

- Gas leakage check at flame turn-on

- Auxiliary gas pressure monitoring

- Automatic gas supply shut-off at turn-off of flame

- Interlock mechanism for nitrous oxide - acetylene gas burner head

- Burner drain liquid level monitoring

- Cooling water flow rate monitoring

- Flashback prevention using auxiliary gas buffer tank at power failure

- Flame sensor error monitoring

- Valve error monitoring

19. Other improvement of function from Z-2010 series

- Each status display in a monitor

- Measurement monitor screen

ABS values and REF values monitored on the window can be saved in a designated file as the monitor measurement result data (in frame/manual analysis). The monitor measurement time range is from 21 to 3600 seconds (set by the second). Files are saved in the text format (*.txt). This function is convenient when numeric data are necessary for a long time

- Automatic dilution setup (in the Graphite Furnace/Autosampler analysis)

At the Check Sample of QC functions, the dilution is calculated automatically from measurement results at the time of exceeding the tolerance.

- “Diluting Cup No.” designation for each element (in the Graphite Furnace/Autosampler analysis)

Z-2000 series use No.60 Diluting cup commonly. This function can setup the diluting cup No. individually.

- The temperature of the clean stage is raised from 2800(C) to 3000(C).

The temperature of the clean stage is raised 3000(C) only the Pyro Tube C HR and the Pyro Tube D HR.

This function prevents the balefulness of memory effect and advantages the measurement of high melting point element.

- [Data file name] Add to a "header".

Even if the paper after printing is shuffled, a [Data file name] is added and printed to a header (upper right portion) so that it can identify which data the paper after 2 page is.

- "Weighting" of an analytical curve is added to the Data Process.

Depending on the range of the working curve, the results of measuring low concentration may be affected by the absorption level of the highly-concentrated standard solution. To reduce such impact, you can use a working curve calculation formula suitable for low concentration.

- "Processing time" is added to the Data Process.

The time range (Start Time and Completed Time) which processes data is specified and the re-calculation becomes possible.

- "Edit & Modifier Name" of data compilation is possible after measurement.

The Modifier name can be edited also after measurement.

Application:

Application: Toxic Elements, Heavy Metals, Environmental Monitoring, Food Safety, Toy Safety, Electronics, Petroleum, Chemical, Academics, Education, Testing and Inspection, Air Quality Monitoring, Metallurgy, Mineralogy, Plastics and Polymer, Cement, Agricultural, Lead in Blood

Techcomp headquarters

Techcomp headquarters  Techcomp regional offices

Techcomp regional offices  Manufacturing, design and R&D facilities

Manufacturing, design and R&D facilities

2606, 26/F., Tower 1, Ever Gain Plaza, 88 Container Port Road, Kwai Chung, N.T., Hong Kong

2606, 26/F., Tower 1, Ever Gain Plaza, 88 Container Port Road, Kwai Chung, N.T., Hong Kong +852-27519488 / WhatsApp/WeChat HK: +852-8491 7250

+852-27519488 / WhatsApp/WeChat HK: +852-8491 7250 techcomp@techcomp.com.hk

techcomp@techcomp.com.hk

Sweep The Concern Us

Sweep The Concern Us