Home· · ·Techcomp college· · ·Application notes

Application notes

Scion Instrument Application Notes AN0008 - Analysis of Boiling Point Distributions in Petroleum Fra

Analysis of Boiling Point Distributions in Petroleum Fractions using Simulated Distillation (ASTM D2887A).

INTRODUCTION

In many regions ASTM D 2887 may be used for determining the boiling point distribution of petroleum products, feedstocks and fractions that have a final boiling point of 538538°C or lower. This provides insight into composition and determining intrinsic product value.

Even though Physical Distillation is still considered the reference method for distillation, and therefore mandatory in many countries for qualifying fuels, Simulated Distillation (SIMDIST) by gas chromatography offers some significant advantages over the physical procedure, making this technique valuable.

Analysis by GC typically has the better precision, more throughput, less hands on time and lower cost per sample

Lastly, SIMDIST requires considerable less sample and should generally be considered the safer of the two techniques.

In addition to the standard method (procedure A), a second procedure has recently been added into D 2887 the accelerated or fast method (procedure B)

This application note demonstrates a solution for D 2887 procedure A for analysing Petroleum products covering a boiling point range of 3636°C to 545545°C This procedure is not suited for biodiesels For gasolines, method D 7096 should be used

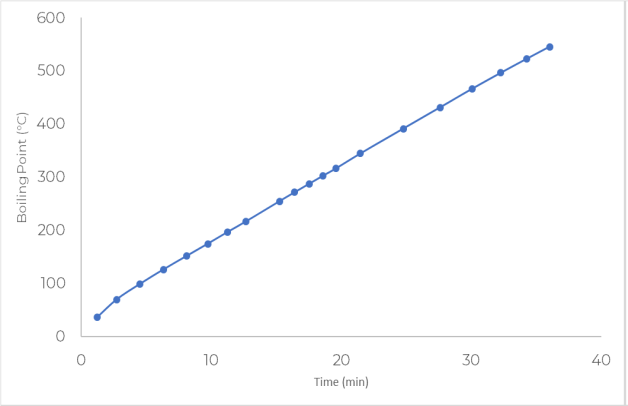

EXPERIMENTAL

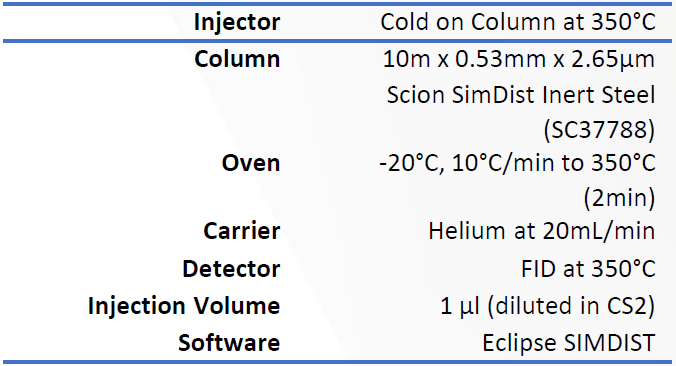

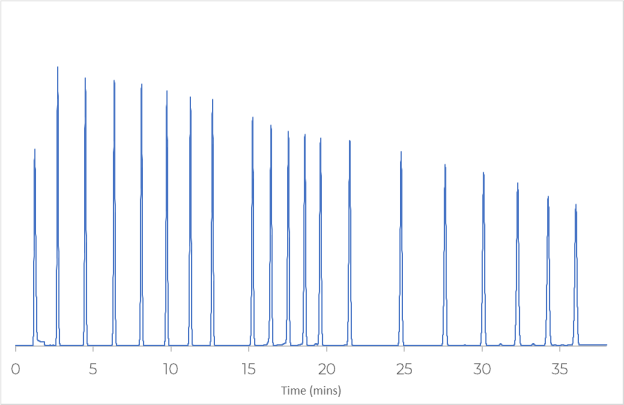

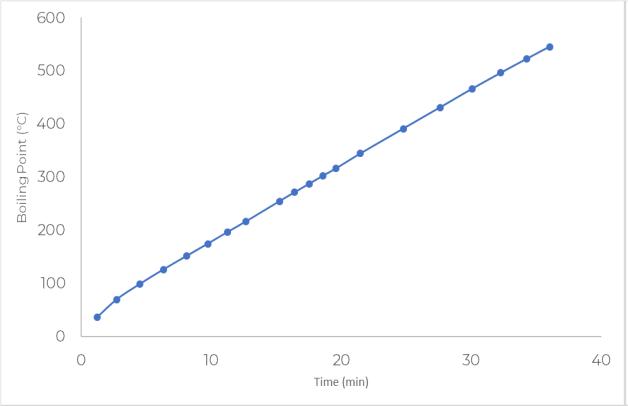

The SCION SimDist analyser comprises of a SCION 456 GC or 436 GC, configured with a cool on column ( injector, a 10 m x 0.53 mm x 2.65 μm SimDist column, and Flame Ionisation. Detector (FID) Analytical conditions for the SimDist analysis can be found in Table 1. A qualitative mixture of normal paraffins (C5 -C44 1 wt ./wt. each in CS2) was used to determine the relationship of boiling point (versus retention time (RT).

All Samples were diluted prior to injection in CS 2 per ASTM D 2887 18 Gasoil samples, diluted in CS 2 were analysed as a quality control

RESULTS

Figures 1 and 2 show the n paraffins mixture, and the resulting RT vs BP calibration curve as constructed by the SIMDIS Software.

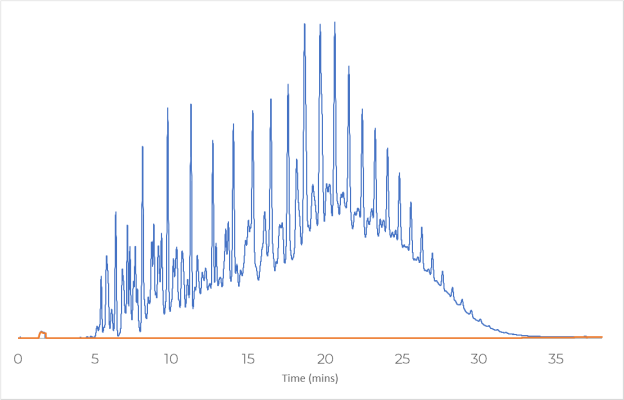

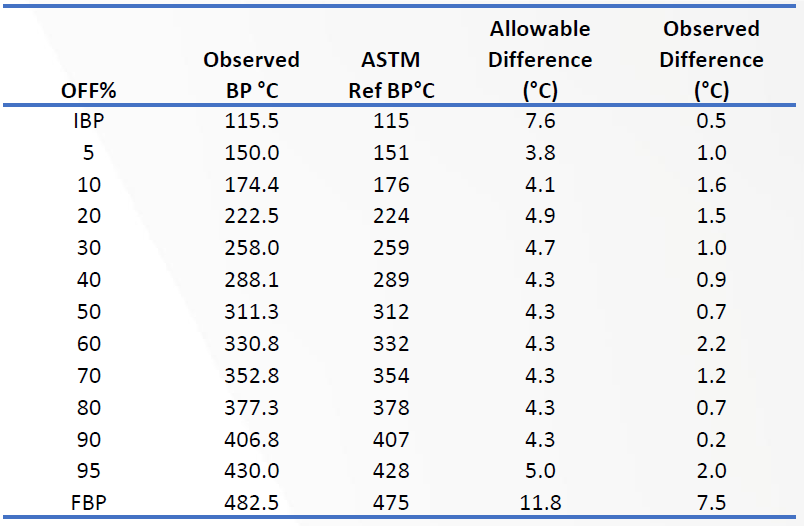

In order to meet the requirements of ASTM D 2887 the reference gas oil sample was analysed The sample was analysed over five consecutive injections as per the ASTM D 2887 method. Figure 3 shows the chromatogram of the reference gas oil sample, with Table 2 showing the total boiling point distribution of the gas sample along with the ASTM D2887 reference values and max deviation criteria.

Differences between Reference BP and Observed BP for each 10

weight slice fraction typically are 2 with exception of the FBP, which was

slightly larger All these are well within the allowable value of the ASTM D

2887 method.

Fig 1. C5 C44 n Paraffins Calibration Mix, 1% in CS2

Fig 2. C5 C44 n-Paraffins RT vs Boiling Point Calibration

Table 2. Observed Values and ASTM Consensus values for Reference Gas Oil 1, Lot # 2

Sample (n=5)

CONCLUSION

It is demonstrated that Scion SIMDIS solution passes criteria as described in ASTM D 2887 procedure A. Differences between observed values and consensus value for the reference gasoil used were generally small, typically 2 or lower, with exception of the FBP.

Please note that:

- Boiling range distributions obtained by this test method are essentially equivalent to those obtained by true boiling point ( distillation (see Test Method D 2892.

- They are not equivalent to results from low efficiency distillations such as those obtained with Test Method D 86 or D 1160.

- The gas chromatographic simulation of this determination can be used to replace conventional distillation methods for control of refining operations

- This test method can be used for product specification testing with the mutual agreement of interested parties 1.

References

1. ASTM D 2887 18 Standard Test Method for Boiling Range Distribution of Petroleum Fractions by Gas Chromatography https :://www astm org/Standards/D 2887 htm

For details, please download the application note

2606, 26/F., Tower 1, Ever Gain Plaza, 88 Container Port Road, Kwai Chung, N.T., Hong Kong

2606, 26/F., Tower 1, Ever Gain Plaza, 88 Container Port Road, Kwai Chung, N.T., Hong Kong +852-27519488 / WhatsApp/WeChat HK: +852-8491 7250

+852-27519488 / WhatsApp/WeChat HK: +852-8491 7250 techcomp@techcomp.com.hk

techcomp@techcomp.com.hk

Sweep The Concern Us

Sweep The Concern Us