Home· · ·Techcomp college· · ·Application notes

Application notes

Himac-Blue 160 – Separation of Clay by Using a Large-Capacity Rotor for the High-Speed Refrigerated

Regarding material that is deemed possible with production at the study level, transfer to the next process (i.e., the production line) is an important issue for manufacturers. ln the separation and purification processes, scaled-up processing is also required for transfer from a minimum amount at the research level to a large amount for production.

The R9A2 angle rotor is a large-capacity rotor with maximum capacity of 1,500 ml, thereby enabling centrifugal separation in a large amount of 6,000 ml = 1500 PP (WM) bottles x 4 pcs] at a time. Even though the maximum diameter of this rotor is about the same ( 1.1 times) as that of conventional rotors its processing capacity is about 1.7 times greater than that of conventional ones indicating that the R9A2 angle rotor is suitable for processing a large amount of material. This article reports the results of centrifugal separation of bentonite -a kind of clay , by using the R9A2 angle rotor.

Content

1. Equipment and associated component

Centrifuge: CR22N high-speed refrigerated centrifuge

Rotor: R9A2 angle Rotor

Centrifugation

vessel: 1500 PP (WM) bottles

2. Separation conditions

Rotation speed: 8,500 rpm

Maximum centrifugal acceleration: 15,100xg

Centrifugation time: 10 minutes

Acceleration/deceleration: “9”/7”

Sample: 1% bentonite suspended solition (colored using bromophenol blue)

Amount of sample: 1,500ml x 4 pcs

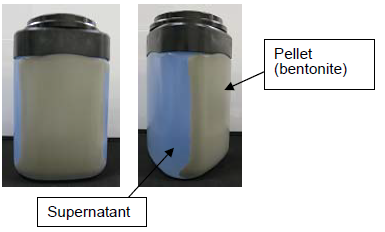

3. Results of separation

|

|

4. Conclusion

After centrifugation, bentonite pelleted on the centrifugal force side of the 1500 PP (WM) bottles. This phenomenon confirms that the R9A2 angle rotor is capable of centrifugating solution inin a maximum amount of 6000ml at a time. Also note that the 1500 PP (WM) bottles used in this article have a large-diameter opening, enabling easy removal of the deposit after centrifugation. Based on the results the time required for a centrifugation experiment is considered shortened due to an increased processing amount and improved efficiency in pellet collection.

Equipment

CR22N High-Speed Refrigerated Centrifuge

R9A2 Angle Rotor

Product Info: Himac CR22N High Speed Refrigerated Centrifuge

Note: CR22GIII is old model. Current model is CR22N

2606, 26/F., Tower 1, Ever Gain Plaza, 88 Container Port Road, Kwai Chung, N.T., Hong Kong

2606, 26/F., Tower 1, Ever Gain Plaza, 88 Container Port Road, Kwai Chung, N.T., Hong Kong +852-27519488 / WhatsApp/WeChat HK: +852-8491 7250

+852-27519488 / WhatsApp/WeChat HK: +852-8491 7250 techcomp@techcomp.com.hk

techcomp@techcomp.com.hk

Sweep The Concern Us

Sweep The Concern Us