product

- Atomic Force Microscope

- FE-SEM

- Hi-SEM

- Optical Interferometry System

- Sample Preparation

- Tabletop Microscope

- Transmission Electronic Microscope

- X-Ray Spectroscopy

- Fluorescence Spectrophotometer

- Amino Acid Analyzer

- Atomic Absorption Spectrophotometer

- Autotitrator

- Mercury Analyzer

- UV-VIS Spectrophotometer

- High Performance Liquid Chromatography

- Thermal Analyzer

- Automatic Moisture and Ash Content Analyzer

- Fluorescence Spectrophotometer

- Fluorescence Steady State & Life Time / Flash Photolysis

- Mercury Analyzer

- Raman Spectroscopy

- UV-VIS Spectrophotometer

- Mass Spectrometer

- FTIR Spectrometer

- Chromatography Data System

- Gas Chromatography

- Gas Chromatography-Mass Spectrometer (GC-MS)

- Liquid Chromatography

- Sampler and sample pretreatment system

- Column and Consumable

- Amino Acid Analyzer

- Anaerobic & Hypoxic Chambers

- Autoclave & Sterilization

- Biological Safety Cabinets & Clean Benches

- Blood bank & Phamacy Freezer

- Cryopreservation Systems

- DNA & RNA Purification

- Environmental Chambers

- Freezer Dryer

- High Capacity Centrifuge

- High Speed Centrifuge

- Lab Water Purification

- Lab Oven & Incubator

- Life Science

- Mixer

- Pipette

- Tabletop Centrifuge

- Ultracentrifuge

- ULT Freezer

- Temperature Forcing System

- Precisa Analytical Balances

- Precisa Micro Balances

- Precisa Precision Balances 0.001g

- Precisa 520 PB/PT Analytical and Precisa balances

- Preicsa 320 XB Series Balances

- Precisa 165 BJ Series Balances

- Precisa 410 SRS/SRC Series Scale

- Precisa 365 EM/330 XM Moisture Analyzers

- Precisa 490 Series Industrial Scales

- Precisa 321 LX/LS-STB Series Stirrer Balances

- Precisa 321 LG Series Balances

- Standard Balances

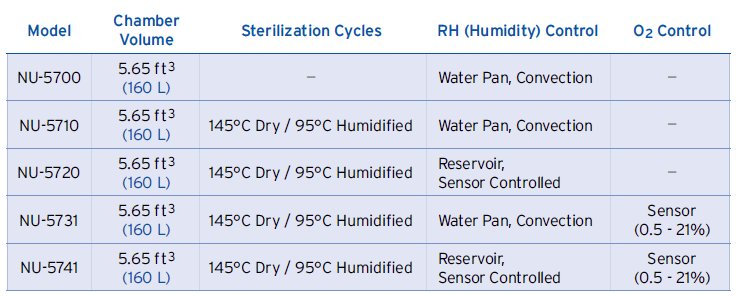

NuAire NU-5700 Series Direct Heat CO2 Incubators

NuAire Direct Heat CO2 Incubators (160L) deliver a reliable controlled in-vitro environment for optimum tissue cell culture growth.

Download- Hong Kong SAR

- China

Direct Heat CO2 Incubator

NuAire CO2 Incubators deliver a dependable and reliable controlled in-vitro environment for optimum tissue cell culture growth as well as the storage and preservation of gametes and animal tissue cell cultures intended for research at or near body temperature, by properly controlling temperature, humidity, CO2 gas, and sterility.

Standard Features

· Large chamber capacity (160L)

· Two Selections of Sterilization Cycle (Except NU-5700)

· No need to remove filters and sensors during sterilization

· ISO Class 5 Clean-Room Chamber

· Infrared CO2 Sensor (higher sensitivity than TC sensors)

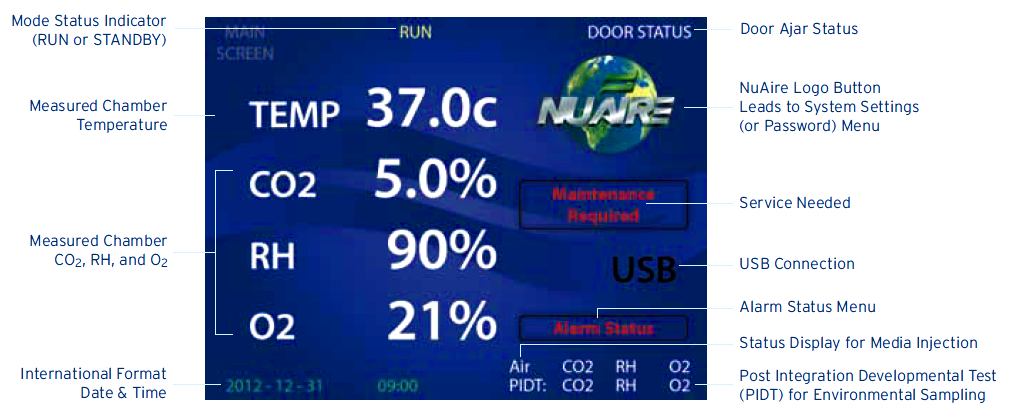

· 7”x 5”Color Touch Control Panel

· Data Storage for Set Points & Performance Record

· Optional RH & O2 Control, Auto Tank Switch, Platform with Casters, Copper Surface, etc.

ISO Class 5 Cleanroom Conditions - Closed Loop HEPA Filtration

· The growth chamber maintains a slightly positive pressure relative to the surrounding lab, preventing entry of contaminants.

· Recirculated chamber air and supply gas pass through 99.99% HEPA filters, with air change every 20 to 30 minutes to minimize cell desiccation.

· A sensor bay continually samples the chamber environment and makes adjustments when needed.

Dual Sterilization Cycles (Except NU-5700)

· The incubators offer a 145°C high-temperature dry cycle, and a 95°C high-temperature humidified cycle to eradicate potential contamination left over in the chamber from user interaction.

· Each cycle can be run as an overnight procedure as part of a regular cleaning plan, perfect when switching cell lines.

· The NuTouch control panel provides step by step directions how to initiate the sterilization process.

· Interior components such as gas sensors and shelving can remain in the chamber during the sterilization process.

Sensitivity and Accuracy of Gas Control

· A microprocessor-based, non-dispersive, single source dual wave infrared (IR) sensor controls CO2 levels within the chamber.

· The wavelengths used are absorbed by only CO2 making the measurement insensitive to other components such as water vapor.

· Advanced design provides a very stable output minimizing drift and requiring less frequent calibration.

The NuTouch Electronic Control System (ECS)

· It creates a unique product experience providing an easy method to control, monitor, and notify.

· Help screens offer a step-by-step guide to assist in procedures such as running a sterilization cycle.

· User activated help pop-up descriptions

· Available in English, Spanish, German & French

· Customizable service reminders

· Alarm notifications

· Visual history performance

· On-screen help

· Password protection

Oxygen Control - Hypoxic Studies (Featured on O2 Control models only)

· For more sensitive cells lines prone to stress and DNA damage, CO2 Incubator models featuring Oxygen control utilize an O2 sensor to monitor oxygen in the growth chamber.

· Nitrogen gas is injected to suppress oxygen to set point. An extensive O2 range applies to various research applications including the brain, eyes, liver, heart, kidneys, and more.

Humidity Control (Featured on RH models only)

· Relative humidity levels up to 90% are achieved in the growth chamber through the use of a 3-liter reservoir external to the chamber.

· The chamber air is routed through the water vapor saturated the air in an evaporate box to add humidity when the RH sensor indicates more humidity is needed to meet set point.

Techcomp headquarters

Techcomp headquarters  Techcomp regional offices

Techcomp regional offices  Manufacturing, design and R&D facilities

Manufacturing, design and R&D facilities

2606, 26/F., Tower 1, Ever Gain Plaza, 88 Container Port Road, Kwai Chung, N.T., Hong Kong

2606, 26/F., Tower 1, Ever Gain Plaza, 88 Container Port Road, Kwai Chung, N.T., Hong Kong +852-27519488 / WhatsApp/WeChat HK: +852-8491 7250

+852-27519488 / WhatsApp/WeChat HK: +852-8491 7250 techcomp@techcomp.com.hk

techcomp@techcomp.com.hk

Sweep The Concern Us

Sweep The Concern Us